Filament Winding: The Core of Efficient GRP Production

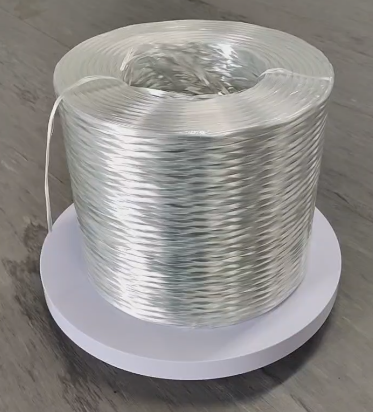

In the world of high-performance composite manufacturing, finding a moulding method that balances speed, precision, and quality is crucial for businesses aiming to stay competitive. Filament winding stands out as a game-changing technique, specifically designed to create strong, reliable Glass Reinforced Plastic (GRP) products. This process involves strategically winding continuous fiberglass filaments around a rotating mandrel, impregnated with resin, to form complex shapes with consistent structural integrity. What makes it so efficient? Unlike traditional moulding methods, filament winding minimizes material waste by precisely layering fibers only where strength is needed, reducing production costs while boosting performance. For industries ranging from aerospace to infrastructure, this means getting durable, lightweight products that meet strict industry standards—without compromising on lead times. Whether you’re producing pressure vessels, pipes, or structural components, filament winding ensures that every GRP product delivers optimal performance, making it a top choice for manufacturers focused on both quality and efficiency.

Why Filament Winding Excels for High-Performance GRP Needs

High-performance GRP products demand more than just basic functionality—they require resistance to corrosion, extreme temperatures, and heavy loads. Filament winding rises to this challenge by leveraging the inherent strengths of fiberglass, such as its exceptional strength-to-weight ratio and electrical insulation properties. The controlled winding process allows for precise fiber orientation, which directly enhances the product’s mechanical performance. For example, in the transportation sector, filament-wound GRP parts reduce vehicle weight, improving fuel efficiency without sacrificing durability. In the chemical industry, these products resist harsh chemicals and corrosive environments, extending service life and reducing maintenance costs. What’s more, filament winding is highly scalable, adapting easily to small-batch prototypes or large-scale production runs. This flexibility makes it ideal for businesses with diverse needs, from custom components to mass-produced parts. By choosing filament winding for your GRP manufacturing, you’re investing in a method that delivers consistent quality, long-lasting performance, and tangible cost savings—all key factors for success in today’s fast-paced industrial landscape.

Industry Applications: Where Filament Winding Makes a Difference

Filament winding’s versatility has made it an indispensable technique across a wide range of industries, each benefiting from its unique advantages. In aerospace, lightweight and high-strength GRP components produced via filament winding help reduce aircraft weight, enhancing fuel efficiency and overall performance. The infrastructure sector relies on filament-wound pipes and tanks for water treatment, oil and gas transportation, and civil engineering projects, thanks to their corrosion resistance and long service life. For the energy sector, especially renewable energy, filament-wound wind turbine blades and storage tanks offer durability in harsh outdoor conditions, supporting sustainable energy goals. Even in sports and leisure, filament winding contributes to high-performance equipment like bicycle frames and boat hulls, where strength and lightness are critical. No matter the industry, filament winding provides tailored solutions that address specific challenges, from extreme environmental conditions to strict performance requirements. By aligning with this advanced moulding method, businesses can meet their customers’ needs more effectively while gaining a competitive edge in their respective markets.

Conclusion

Filament winding is more than just a moulding method—it’s a strategic choice for businesses seeking efficient, high-performance GRP products. Its ability to deliver consistent quality, reduce waste, and adapt to diverse industry needs makes it stand out in the composite manufacturing landscape. From aerospace to infrastructure, every sector benefits from the strength, durability, and cost savings that filament winding provides. By leveraging this advanced technique, manufacturers can not only meet but exceed customer expectations, producing GRP products that perform reliably in even the most demanding conditions. Whether you’re looking to optimize production processes, cut costs, or enhance product performance, filament winding offers a proven solution that drives success. Embrace this efficient moulding method and take your GRP manufacturing to the next level.