The Importance of Solid-Liquid Separation in Industrial Processing

In the world of industrial processing, the efficiency of solid-liquid separation is crucial. Whether in pharmaceuticals, food production, or wastewater treatment, the ability to effectively separate solids from liquids can significantly influence product quality and operational costs. Centrifuges, as advanced separation devices, play a pivotal role in optimizing these processes, ensuring that industries can meet their production goals while maintaining high standards of quality.

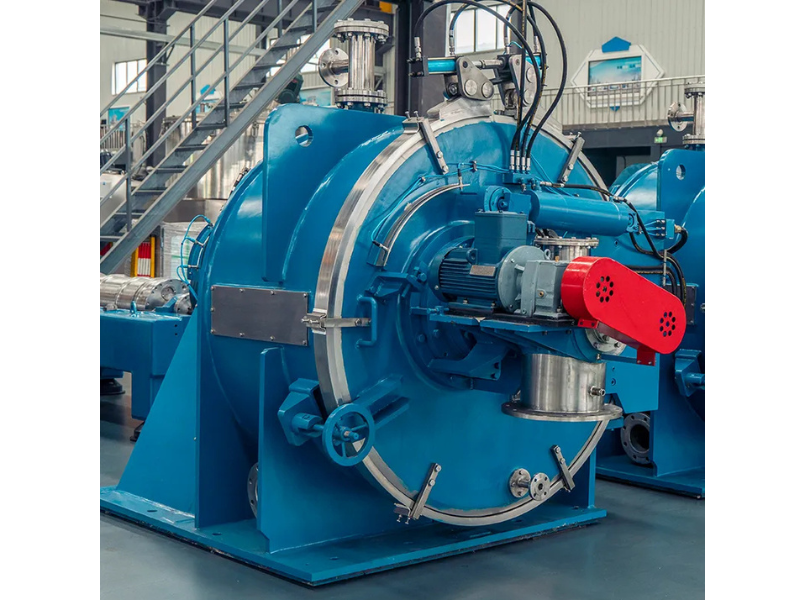

How Centrifuges Work: The Science Behind Centrifugal Force

Centrifuges operate on the principle of centrifugal force, which accelerates the separation process by utilizing high rotational speeds. This technology allows for the rapid and efficient separation of solids from liquids, which is essential in various sectors. For instance, in the food industry, centrifuges are employed to clarify juices and separate fats from liquids, resulting in higher quality products and reduced waste. The ability of centrifuges to handle large volumes of materials makes them indispensable in high-throughput environments where time and efficiency are of the essence.

The Versatility of Centrifuges: Adapting to Industry-Specific Needs

One of the key advantages of centrifuges is their versatility. They can be tailored to meet specific operational requirements, such as varying speeds and configurations, to accommodate different materials and separation needs. This adaptability allows industries to optimize their processes further. For example, in the pharmaceutical sector, centrifuges are used to separate cell cultures and purify proteins, which are critical steps in drug development and manufacturing. The precision and reliability of centrifuges ensure that these processes are executed flawlessly, minimizing the risk of contamination and enhancing product purity.

Cost-Effectiveness: How Centrifuges Reduce Operational Expenses

Moreover, the use of centrifuges contributes to cost-effectiveness in solid-liquid separation processes. By significantly reducing the time required for separation, these machines lower operational costs and increase productivity. The efficient removal of solids from liquids also leads to better resource management, as it allows for the recovery of valuable materials that would otherwise be lost. In wastewater treatment, for instance, centrifuges help in reclaiming water for reuse while ensuring that solid waste is effectively processed, contributing to sustainable practices.

Continuous Operation: Ensuring Uninterrupted Industrial Production

Another notable benefit of centrifuges is their ability to operate continuously, providing a consistent output without the need for frequent interruptions. This continuous operation is particularly advantageous in large-scale industrial applications, where downtime can lead to significant financial losses. By incorporating centrifuges into their processes, companies can achieve a higher level of operational efficiency and maintain a steady production flow, which is vital in competitive markets.

Modern Centrifuge Features: Safety, Usability, and Energy Efficiency

In addition to their operational benefits, modern centrifuges are designed with advanced safety features and user-friendly controls. This ensures that operators can easily manage and monitor the separation process, reducing the risk of accidents and enhancing workplace safety. Furthermore, many centrifuges are built with energy-efficient technologies that minimize power consumption, aligning with global sustainability goals and reducing the environmental impact of industrial operations.

Centrifuges: A Cornerstone of Optimized and Sustainable Industrial Processes

In conclusion, centrifuges are integral to improving solid-liquid separation processes across various industries. Their ability to enhance efficiency, reduce costs, and ensure product quality makes them a valuable investment for any organization looking to optimize its operations. As industries continue to evolve and demand higher standards, the role of centrifuges will only become more critical in achieving these objectives. By embracing this technology, businesses can not only improve their productivity but also contribute to a more sustainable future.