In today’s industrial landscape, optimizing your dust collection system is crucial for enhancing performance and ensuring a safe working environment. A well-functioning dust collection system not only improves air quality but also increases operational efficiency. This article explores various strategies to optimize your dust collection system, ensuring you get the best performance possible.

Understanding Your Dust Collection System

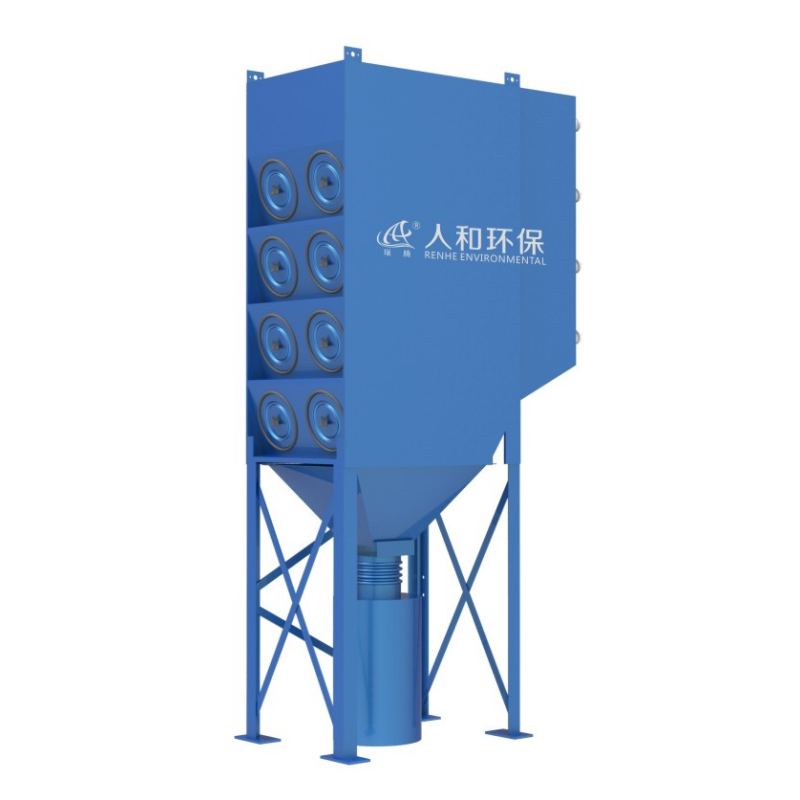

Before diving into optimization techniques, it’s essential to understand the components of your dust collection system. Key elements include the dust collector, ductwork, and filtration systems. Each part plays a vital role in maintaining air quality and efficiency. Regular maintenance and monitoring of these components can significantly enhance the overall performance of your dust collection system.

Regular Maintenance for Peak Performance

One of the most effective ways to optimize your dust collection system is through regular maintenance. This includes cleaning filters, checking for leaks in ductwork, and ensuring that all components are functioning correctly. A well-maintained dust collection system minimizes downtime and maximizes efficiency, leading to a safer and more productive work environment. Implementing a routine maintenance schedule will help you catch potential issues before they escalate, ensuring your system operates at peak performance.

The choice of filters is critical to the efficiency of your dust collection system. Selecting high-quality filters that are appropriate for your specific application can significantly improve dust capture rates. Consider factors such as particle size, airflow requirements, and filter lifespan when making your selection. Upgrading to advanced filtration technologies can also enhance your system’s performance and reduce the frequency of filter changes, ultimately saving you time and money.

The design of your ductwork can greatly impact the efficiency of your dust collection system. Ensure that the ductwork is properly sized and configured to minimize bends and turns, which can cause airflow resistance. Utilizing smooth, straight ducts will improve air velocity and increase the overall effectiveness of your dust collection system. Additionally, regularly inspecting the ductwork for blockages or damage can help maintain optimal airflow.

Implementing Automation and Monitoring Technologies

Incorporating automation and monitoring technologies into your dust collection system can lead to significant performance enhancements. Automated systems can adjust airflow based on real-time dust levels, ensuring that your system operates efficiently at all times. Monitoring technologies can provide valuable insights into system performance, allowing you to make data-driven decisions to optimize operations further. By leveraging these technologies, you can enhance the reliability and efficiency of your dust collection system.

Employee Training and Awareness

Lastly, ensuring that your employees are well-trained in the operation and maintenance of the dust collection system is vital. Regular training sessions can help staff understand the importance of the system and how to operate it effectively. Encouraging awareness about dust management practices can lead to better compliance and proactive measures in maintaining the system, ultimately contributing to improved performance.

In conclusion, optimizing your dust collection system is essential for enhancing performance, ensuring safety, and maximizing efficiency in your operations. By focusing on regular maintenance, selecting the right filters, optimizing ductwork design, implementing automation, and training employees, you can significantly improve the effectiveness of your dust collection system. Investing in these strategies not only benefits your organization but also contributes to a healthier work environment.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://accounts.binance.com/en-ZA/register?ref=B4EPR6J0