Single Yarn: The Core Foundation of Glassfiber Roving for FRP Moulding

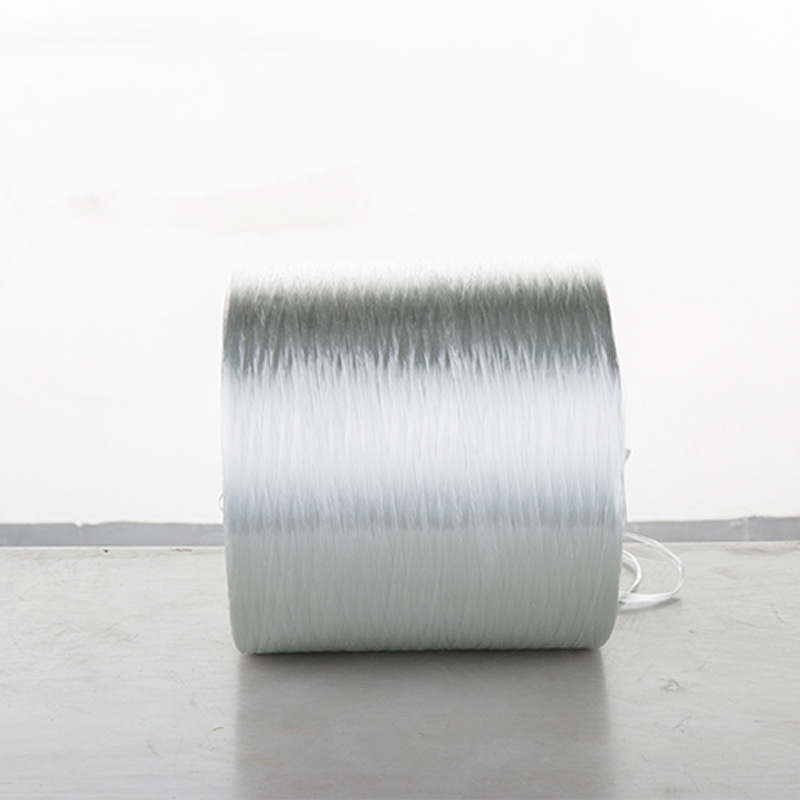

When it comes to FRP (Fiber-Reinforced Plastic) moulding, the quality of glassfiber roving directly determines the final product’s strength, durability, and reliability. At the heart of every high-performance glassfiber roving lies a key component: single yarn. Often overlooked, single yarn is the basic building block that weaves together to form the robust roving used in countless industrial applications. Unlike ordinary fibers, single yarn for glassfiber roving is engineered to deliver exceptional tensile strength, corrosion resistance, and compatibility with resin systems—properties that are non-negotiable for FRP products operating in harsh environments.

For manufacturers in sectors like transportation, aerospace, building materials, and infrastructure, the performance of single yarn translates directly to product competitiveness. Imagine a wind turbine blade or a chemical storage tank: these products rely on glassfiber roving to withstand extreme forces, temperature fluctuations, and corrosive substances. High-quality single yarn ensures that the roving maintains structural integrity, preventing premature wear and tear. This not only extends the lifespan of the end product but also reduces maintenance costs and downtime for businesses—critical factors in today’s fast-paced industrial landscape.

How Single Yarn Enhances FRP Moulding Performance

The role of single yarn in glassfiber roving goes beyond mere structural support; it optimizes the entire FRP moulding process. Single yarn with consistent thickness and uniform fiber distribution ensures smooth resin impregnation, eliminating gaps or weak points in the final composite. This results in products with superior dimensional stability, meaning they retain their shape even under heavy loads or environmental stress. Whether it’s a lightweight aerospace component or a heavy-duty infrastructure part, the right single yarn ensures that the glassfiber roving performs reliably across diverse use cases.

Another key advantage of premium single yarn is its design flexibility. Manufacturers can customize single yarn properties—such as fiber length, strength, and surface treatment—to meet specific application requirements. For example, single yarn used in electrical and electronic components prioritizes electrical insulation, while those for energy-saving applications focus on thermal efficiency. This versatility allows businesses to tailor their FRP products to exact needs, giving them a competitive edge in niche markets. Additionally, high-quality single yarn minimizes waste during production, as it processes consistently and reduces the risk of defects.

Choosing the Right Single Yarn for Your FRP Moulding Needs

With so many options available, selecting the right single yarn for glassfiber roving can be a daunting task. The key is to partner with a supplier that specializes in high-performance fiberglass solutions, with a proven track record of delivering consistent quality. Look for single yarn that meets industry standards for tensile strength, corrosion resistance, and resin compatibility. It’s also important to consider technical support—suppliers who can advise on material selection based on your specific application needs can save you time and resources.

Reliable suppliers understand that every FRP project is unique. They offer a range of single yarn options tailored to different sectors, from sports leisure equipment to chemical field applications. By choosing a supplier with extensive experience in the fiberglass industry, you gain access to not just high-quality products but also valuable expertise. This collaboration ensures that your glassfiber roving performs optimally, helping you build stronger, more competitive products that stand out in the market.

Conclusion

Single yarn is far more than a basic component of glassfiber roving—it’s the backbone of high-performance FRP moulding. Its exceptional strength, durability, and versatility make it indispensable for manufacturers across industries, from aerospace to infrastructure. By investing in premium single yarn, businesses can enhance product quality, reduce costs, and gain a competitive edge in today’s demanding market. When paired with a trusted supplier that prioritizes technological innovation and customer satisfaction, single yarn becomes a key driver of success. For anyone looking to elevate their FRP products, choosing the right single yarn is the first step toward building stronger, more reliable solutions that deliver long-term value.