Choosing parts in manufacturing and precision engineering can heavily impact the results in the efficiency of a laser system and the performance. While some parts are more important than others and more often thought about, laser fiber lenses are often overlooked. This article aims to explain the impact of selecting the right laser fiber lens and the potential consequences of poor selection.

In-Depth Information about Fiber Laser Lenses

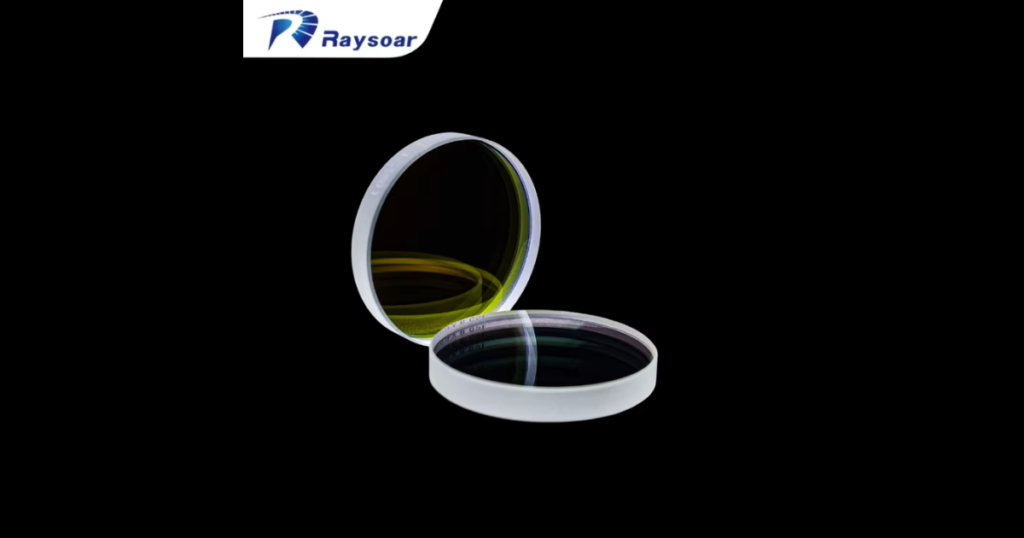

In the production of laser engraved items, objects and items are cut with precision. Laser fiber lenses focuses the beam and determines the quality of the cut. Poor quality lenses results in poor beam divergence and lack of depth which leads to a poor quality end product. Investing in quality lenses greatly improves the production quality and reduces the wastage of material.

Different Options for Fiber Laser Lenses

Different applications require different fiber laser lenses. Some lenses work better for metal cutting and some for engraving, thus, needing to know the exact requirements of your project is very helpful when purchasing a fiber laser lens. Besides this, having the correct lens coating, focal length, and diameter will help the lens work better with your laser system. Having the correct type will improve the working efficiency of the system and lower the operational costs.

Quality of Lenses and System Performance

The overall system performance is influenced by the fiber laser unit lenses. If the lenses are of high quality, they can tolerate high system operational temperatures, minimizing the need for regular lens replacements and system maintenance. This minimizes the operational costs of the system by cutting downtime. Additionally, high quality laser unit lenses will improve beam quality, precision, and laser work detail. Lower quality lenses will not allow you to do very detailed work. Therefore, the quality of your lens system is extremely important to improve the quality of work.

Cost Efficiency and Long-Term Benefits

Choosing the cheapest option for fiber laser lenses can be very costly in the long run. Cheap lenses tend to be poor quality and cause inefficient beam performance leading to wasted energy and costly replacements. On the other hand, investing in quality fiber laser lenses can save businesses money while improving productivity and energy efficiency for laser cutters. Quality lenses also improve workplace conditions, minimize errors and defects, and improve overall customer satisfaction.

Overall, the quality and type of fiber laser lenses you choose, impact the overall success of your projects. Manufacturers are able to save on expenses, improve operational productivity, and achieve the desired laser engraving results if the lenses are chosen correctly. The right lenses benefit the immediate projects and support growing and succeeding in the laser engraving business in the future.