Precision Cleaning Preparation with Industrial Cleaning Machine

Replacing a camshaft in a heavy-duty truck engine starts with thorough preparation, and industrial precision cleaning is non-negotiable. The engine’s internal components, especially the camshaft housing and related parts, accumulate grease, carbon deposits, and debris over long-term use. These contaminants can affect the fit of the new camshaft and lead to premature wear. Using a high-quality Industrial Precision Cleaning Machine ensures deep, residue-free cleaning of all components. Unlike ordinary cleaning tools, this specialized equipment uses advanced water-based cleaning technology that is safe for metal materials—no corrosion, no damage to sensitive parts. It penetrates tiny gaps to remove stubborn grime, creating a clean surface for the new camshaft installation. This step not only improves the replacement accuracy but also extends the service life of the engine after maintenance.

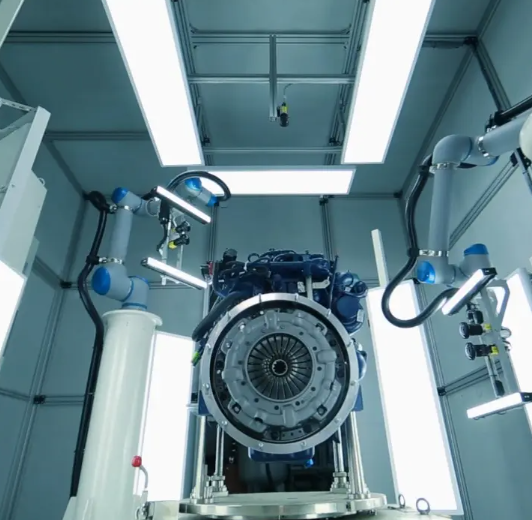

Visual Inspection Equipment for Component Integrity Check

After cleaning, verifying the integrity of parts with Intelligent Visual Inspection Equipment is critical. When replacing a camshaft, it’s not enough to just install a new part—you need to ensure that accompanying components like lifters, pushrods, and timing chains are in good condition. Visual Inspection Equipment uses high-resolution imaging and intelligent analysis to detect microscopic cracks, wear, or deformation that the human eye might miss. It can quickly identify issues such as uneven wear on lifter surfaces or subtle bends in pushrods, which could cause camshaft failure if overlooked. This precision inspection tool provides objective, accurate data, helping technicians make informed decisions about whether to repair or replace auxiliary parts. By integrating this equipment into the replacement process, you minimize the risk of post-maintenance breakdowns and ensure the engine operates at peak performance.

Water-Based Detergent for Safe Post-Replacement Cleaning

Once the new camshaft is installed, a final cleaning with Water-Based Industrial Detergent is essential to remove any residual particles from the assembly process. Traditional solvent-based cleaners can leave toxic residues or damage rubber seals, but water-based detergents are environmentally friendly, non-corrosive, and safe for all engine materials. They effectively clean the external surfaces of the engine and surrounding areas, eliminating dust, oil stains, and metal shavings that could enter the engine during assembly. Additionally, these detergents offer temporary rust protection, preventing moisture from causing corrosion on exposed metal parts before the engine is put back into service. This final cleaning step ensures the engine is free from contaminants, reducing friction and wear between moving parts and enhancing overall reliability.

Post-Replacement Validation with Industrial-Grade Tools

After completing the camshaft replacement and cleaning, validating the installation with professional tools is the last key step. While visual checks are helpful, Industrial Precision Cleaning Machine and Visual Inspection Equipment can be used again to confirm the quality of the work. The cleaning machine ensures no hidden debris remains inside the engine, and the visual inspection equipment verifies that the camshaft is properly aligned, with no misalignment or contact issues. This double-check process eliminates potential errors, such as incorrect torque settings or improper seating of components. For heavy-duty truck operators, this level of validation means fewer unexpected breakdowns, reduced downtime, and lower long-term maintenance costs. Investing in these industrial-grade tools transforms a standard camshaft replacement into a high-quality, durable maintenance service.

Conclusion

Replacing a camshaft in a heavy-duty truck engine requires precision, thoroughness, and the right tools. From pre-installation cleaning with Industrial Precision Cleaning Machine to component inspection with Intelligent Visual Inspection Equipment, and post-installation care with Water-Based Industrial Detergent, each step plays a vital role in ensuring successful maintenance. These industrial solutions not only simplify the replacement process but also enhance the engine’s performance, durability, and safety. For businesses relying on heavy-duty trucks, using professional cleaning and inspection equipment means minimizing downtime, reducing repair costs, and maximizing operational efficiency. Trust in high-quality industrial tools to make camshaft replacement a seamless, reliable process that keeps your fleet on the road longer.