Pre-Cleaning Preparation for Gas Generators

Before diving into cleaning your gas generator, safety and preparation are non-negotiable. First, turn off the generator and disconnect it from all power sources—this prevents accidental startup and electrical hazards. Allow the unit to cool down completely; hot components can cause burns and may react dangerously with cleaning agents. Next, gather essential tools: a soft-bristle brush, lint-free cloths, compressed air (for hard-to-reach areas), a mild detergent (avoid harsh chemicals that damage parts), and a container for collecting debris. For specific models like natural gas or hydrogen generators, check the manufacturer’s manual for any special precautions—some components may require gentle handling to preserve their performance. Taking these steps ensures a smooth, safe cleaning process that protects both you and your equipment.

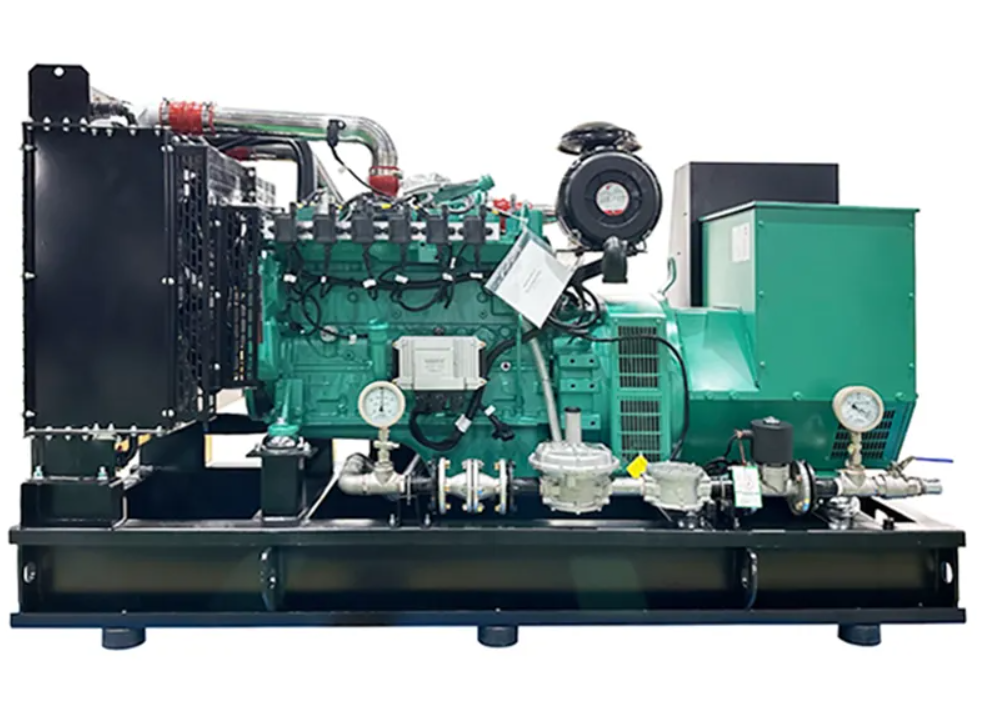

Cleaning the Exterior of Gas Generators

The exterior of your gas generator is the first line of defense against dirt, dust, and debris, so keeping it clean is vital for overall functionality. Start by wiping down the surface with a damp lint-free cloth to remove loose dirt. For stubborn stains, mix a small amount of mild detergent with water and gently scrub using a soft-bristle brush—avoid abrasive materials that scratch the casing. Pay extra attention to air intake grilles and vents; clogged openings restrict airflow, leading to overheating and reduced efficiency. For LPG or methanol generators, ensure fuel connections are dry and free of residue to prevent leaks. After cleaning, dry the exterior thoroughly with a clean cloth to prevent moisture buildup, which can cause rust or corrosion over time. A clean exterior not only looks professional but also helps you spot potential issues like cracks or leaks early.

Maintaining Internal Components of Gas Generators

While the exterior is visible, internal components like the air filter, spark plugs, and fuel system are critical to your gas generator’s performance—neglecting them can lead to breakdowns. Begin with the air filter: remove it and tap gently to shake off dust, or replace it if it’s heavily soiled (refer to your manual for replacement intervals). For natural gas generators, clean the fuel injectors with a specialized cleaner to remove carbon deposits that hinder fuel flow. Spark plugs should be inspected and cleaned with a wire brush to remove fouling; if the electrodes are worn, replace them promptly. Hydrogen generators require extra care with fuel cell components—use compressed air to blow away dust, and avoid touching sensitive parts with bare hands. Always ensure all internal parts are completely dry before reassembling to prevent electrical shorts or fuel system damage. Regular internal cleaning keeps your generator running smoothly, even under heavy loads.

Post-Cleaning Inspection and Safety Checks for Gas Generators

After cleaning, a thorough inspection is crucial to confirm your gas generator is ready for use. Reconnect all components securely and check for loose wires, damaged hoses, or leaking connections—pay special attention to fuel lines on LPG and methanol generators. Start the generator and let it run for 5-10 minutes; listen for unusual noises (like knocking or squealing) and check for abnormal vibrations. Monitor the exhaust for excessive smoke, which could indicate incomplete combustion or leftover debris. For hydrogen generators, verify that the fuel cell is operating efficiently and that there are no gas leaks. Finally, document the cleaning date and any maintenance performed—this helps track your generator’s service history and ensures you stay on top of future maintenance. A post-cleaning inspection not only guarantees safety but also gives you peace of mind knowing your generator is in top condition.

Conclusion

Properly cleaning and maintaining your gas generator is the key to extending its lifespan, ensuring reliable performance, and maximizing efficiency. From pre-cleaning safety steps to detailed internal maintenance and post-cleaning inspections, each step plays a vital role in keeping your equipment in optimal shape—whether it’s a natural gas, LPG, methanol, or hydrogen generator. Regular cleaning reduces the risk of breakdowns, lowers repair costs, and ensures your generator is ready when you need it most, whether for emergency backup power, off-grid projects, or industrial use. Investing time in proper cleaning not only protects your investment but also enhances the overall performance of your gas generator. For high-quality gas generators designed for durability and efficiency, trust a professional supplier that prioritizes reliability and sustainability—ensuring your energy needs are met with long-lasting, high-performance equipment.